IoT in Production: From Manual to Marvel – The Rise of Smart Factories is revolutionizing manufacturing, transforming factories from dusty, labor-intensive environments into intelligent, automated marvels. Imagine a world where machines communicate seamlessly, predicting maintenance needs before failures occur, and optimizing production lines in real-time. This transformation, driven by the Internet of Things, is reshaping the future of work and production, ushering in an era of unprecedented efficiency and productivity.

This journey explores the evolution of manufacturing, detailing the key concepts of IoT in industrial settings. We’ll dissect the differences between traditional and IoT-enabled production lines, highlighting the benefits of increased efficiency, quality control, and safety. We’ll examine the enabling technologies, implementation strategies, case studies, and the critical challenges and considerations that accompany this exciting shift. Finally, we’ll gaze into the future, exploring the predicted trends and advancements that will shape the future of smart factories.

Introduction to IoT in Manufacturing

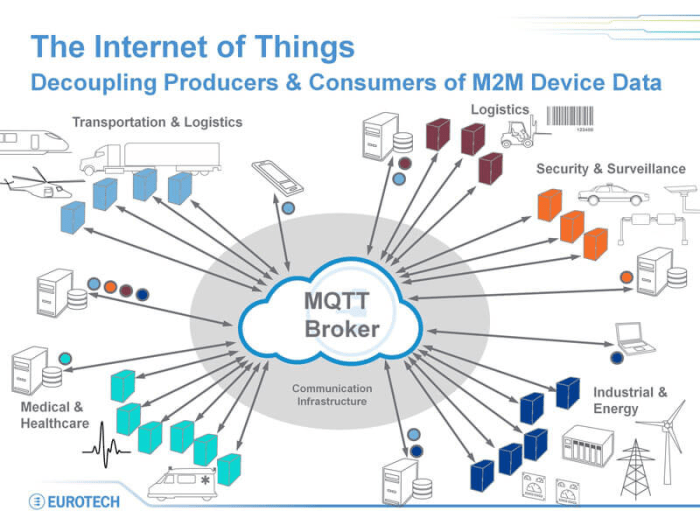

Manufacturing has undergone a remarkable transformation, progressing from manual labor to sophisticated automated systems. Early stages relied heavily on human intervention, leading to inconsistencies and inefficiencies. Automation, with its precision and speed, dramatically increased productivity and quality. Now, the Internet of Things (IoT) is revolutionizing the industry further, connecting machines, devices, and data to create smarter, more responsive production lines.The Internet of Things, in essence, is a network of interconnected physical devices embedded with sensors, actuators, and communication capabilities.

In manufacturing, this translates to machines, sensors, and equipment communicating with each other and central systems, enabling real-time data collection, analysis, and decision-making. This connectivity empowers manufacturers to optimize processes, enhance efficiency, and improve product quality.

Key Differences Between Traditional and IoT-Enabled Production Lines

Traditional production lines often operate in isolation. Data collection is limited, typically relying on manual record-keeping and sporadic checks. In contrast, IoT-enabled lines leverage real-time data from interconnected devices, providing continuous insights into performance and potential issues. This enables proactive maintenance, predictive modeling, and dynamic adjustments to optimize the production process. The ability to monitor and manage assets remotely, predict equipment failures, and adjust production in real time are key differentiators.

Types of Sensors and Actuators in Smart Factories

Understanding the range of sensors and actuators used in smart factories is crucial. These devices form the backbone of data collection and actuation within the IoT framework. Their diverse capabilities allow for monitoring various parameters, from temperature and pressure to vibration and position, enabling a holistic view of the manufacturing process.

| Sensor Type | Description | Common Applications in Manufacturing |

|---|---|---|

| Temperature Sensors | Measure temperature at various points in the production process. | Monitoring oven temperatures, controlling cooling systems, and detecting overheating in machines. |

| Pressure Sensors | Measure pressure levels in different systems. | Monitoring hydraulic and pneumatic systems, detecting leaks, and ensuring proper pressure levels in molding processes. |

| Vibration Sensors | Detect vibrations in machinery to identify potential faults or wear and tear. | Monitoring machine health, predicting equipment failures, and preventing costly breakdowns. |

| Proximity Sensors | Detect the presence or absence of objects within a certain range. | Counting parts on a conveyor belt, controlling assembly processes, and ensuring proper placement of components. |

| Motion Sensors | Track the movement of objects or people. | Monitoring the flow of materials on assembly lines, optimizing robot movements, and detecting deviations in the manufacturing process. |

| Light Sensors | Measure the intensity of light. | Monitoring lighting levels in assembly areas, adjusting machine speeds based on ambient light, and optimizing visual inspection processes. |

| Actuators (Example: Motors) | Translate data from sensors into physical actions. | Adjusting machine speeds, controlling robotic arms, and implementing automated quality checks. |

Benefits of IoT in Production

The manufacturing landscape is rapidly evolving, with the integration of Internet of Things (IoT) technologies driving significant transformations. IoT’s ability to connect machines, sensors, and data systems creates unprecedented opportunities for efficiency gains, enhanced quality, and improved safety in factories. This shift empowers manufacturers to optimize operations, reduce costs, and deliver better products.IoT empowers companies to collect and analyze vast amounts of real-time data from connected devices.

This data-driven approach provides a granular understanding of production processes, enabling proactive maintenance, predictive modeling, and ultimately, a higher degree of control. The result is improved productivity, reduced downtime, and a more responsive and agile manufacturing environment.

Increased Efficiency and Productivity Gains

Real-time insights into machine performance and operational parameters are crucial for optimizing production lines. IoT sensors track equipment health, predicting potential failures before they occur. This proactive approach minimizes unplanned downtime, significantly boosting overall equipment effectiveness (OEE). Predictive maintenance schedules, based on real-time data, ensure that maintenance is performed only when necessary, further reducing costs and increasing output.

Automated processes, triggered by sensor data, can streamline workflows and improve production speeds.

Improvements in Quality Control and Reduced Waste

IoT sensors can monitor various production parameters, such as temperature, pressure, and material composition. Continuous monitoring enables manufacturers to identify deviations from optimal conditions, preventing defects and ensuring consistent quality. Real-time data analysis facilitates quicker identification of issues, allowing for rapid corrective actions. This approach minimizes waste by reducing defective products and optimizing resource usage. Automated quality checks can catch anomalies at any stage, minimizing the output of flawed products.

Enhanced Safety Measures and Worker Well-being

IoT-enabled safety systems can monitor worker activity, identify potential hazards, and trigger alerts in real-time. This proactive approach enhances worker safety by reducing the risk of accidents. Wearable sensors track worker movements and identify potentially dangerous situations. IoT can also monitor environmental conditions, ensuring a safe and comfortable working environment for all personnel. Real-time data on workplace conditions can optimize employee well-being, potentially reducing fatigue and injuries.

Smart factories are revolutionizing production, moving from manual processes to automated marvels powered by IoT. Choosing the right IoT Consulting Services: Everything You Need To Know is crucial for navigating this transformation and maximizing your ROI. This detailed understanding will ensure your factory stays ahead of the curve in this exciting new era of IoT-driven production.

Comparison of Costs and Benefits of Implementing IoT Solutions

| Manufacturing Scenario | Potential Costs | Potential Benefits |

|---|---|---|

| Small Batch Production | Relatively lower initial investment, but potential for high integration complexity. | Improved quality control, reduced waste, and potential for improved production time and throughput. |

| Large-Scale Production | Higher initial investment, but significant potential for economies of scale in long term. | Increased efficiency, reduced downtime, significant reduction in operational costs, and improved production throughput. |

| Custom Manufacturing | Moderate initial investment, but customization costs may be high. | Enhanced quality control, reduced errors, potential for improved production flexibility, and better customer satisfaction. |

This table provides a basic comparison. Specific costs and benefits will vary based on the individual manufacturing process, the complexity of the IoT implementation, and the specific technologies used.

Key Technologies Enabling Smart Factories

The transition to smart factories hinges on a powerful combination of technologies. These technologies not only automate processes but also unlock unprecedented levels of data-driven insights, enabling proactive maintenance, optimized resource allocation, and ultimately, higher profitability. This evolution from manual to machine-driven operations is dramatically changing the landscape of manufacturing.The key enabling technologies are not isolated islands; they work in concert to create a sophisticated ecosystem.

Cloud computing provides the scalable infrastructure, big data analytics unlocks the value from collected data, and AI empowers systems to learn and adapt. This intricate dance of technology creates a self-optimizing manufacturing environment, setting the stage for greater efficiency and resilience.

Cloud Computing for Scalability and Data Storage

Cloud platforms offer the scalability and flexibility needed for the massive amounts of data generated by IoT devices in a manufacturing setting. Their elasticity allows for rapid scaling up or down based on demand, eliminating the need for significant upfront investment in on-site infrastructure. This flexibility translates to cost savings and quicker deployment of new features and applications. Furthermore, cloud storage provides secure and reliable access to data, enabling real-time analysis and decision-making.

This data accessibility is critical for optimizing processes and improving efficiency.

Big Data Analytics for Actionable Insights

The deluge of data from connected machines in a smart factory requires sophisticated analysis to be truly valuable. Big data analytics tools extract meaningful insights from this raw data, identifying patterns, anomalies, and trends. These insights enable predictive maintenance, enabling proactive interventions to avoid costly downtime. Furthermore, they allow for optimization of production processes, resource allocation, and supply chain management, ultimately boosting efficiency and profitability.

Artificial Intelligence for Intelligent Automation, IoT in Production: From Manual to Marvel – The Rise of Smart Factories

AI is rapidly transforming manufacturing processes. Machine learning algorithms can analyze data to identify patterns, predict equipment failures, and optimize production schedules. This proactive approach reduces downtime and enhances operational efficiency. AI also facilitates intelligent decision-making in real-time, allowing factories to respond dynamically to changing conditions and market demands. Examples include AI-powered quality control systems that identify defects with near-perfect accuracy.

Connectivity Protocols for Seamless Data Exchange

Connectivity protocols are the lifeblood of a smart factory, facilitating the seamless flow of data between machines, devices, and the cloud. 5G, with its high bandwidth and low latency, is revolutionizing industrial communication. Wi-Fi, while less robust in high-density industrial environments, remains crucial for connecting various devices within a smaller space. The choice of protocol depends on the specific needs of the application and the density of the industrial environment.

Careful consideration must be given to ensure reliable and secure communication.

Industrial Automation Systems

Different types of industrial automation systems cater to diverse manufacturing needs. These systems range from programmable logic controllers (PLCs) to industrial robots and advanced control systems. PLCs are essential for automating repetitive tasks and controlling individual machines. Industrial robots are vital for complex assembly operations and heavy lifting. Advanced control systems manage entire production lines, optimizing workflows and integrating various automation elements.

Each system plays a crucial role in streamlining production and enhancing efficiency.

Security Considerations for IoT Deployments

| Security Concern | Mitigation Strategy |

|---|---|

| Data breaches | Robust encryption and access controls are essential to protect sensitive data. Regular security audits and vulnerability assessments are also crucial. |

| Malware attacks | Employ intrusion detection systems and firewalls to monitor and block malicious activity. Regular software updates and patching are essential to address vulnerabilities. |

| Unauthorized access | Multi-factor authentication and strict access controls are vital to prevent unauthorized access to sensitive data and systems. |

| Physical security | Secure physical access to equipment and networks is vital. This includes using robust security measures for physical access control. |

Implementation Strategies for IoT in Production

Transforming your factory floor into a connected, intelligent ecosystem requires a well-defined implementation strategy. A phased approach, focusing on key areas and managing expectations, is crucial for success. It’s not just about installing sensors; it’s about integrating them seamlessly into existing workflows and processes. This involves meticulous planning, careful selection of technologies, and a willingness to adapt as you learn and refine the process.A successful IoT implementation in production hinges on a robust strategy that considers the nuances of your specific environment.

This includes understanding your current infrastructure, identifying clear goals, and creating a roadmap that allows for gradual evolution and continuous improvement. This isn’t a one-size-fits-all endeavor; customization is key to achieving maximum ROI.

Phased Implementation Plan

A phased implementation plan is essential for a smooth transition to an IoT-driven factory. It allows for careful testing, gradual integration, and continuous improvement based on real-world feedback. A phased rollout minimizes disruption and maximizes the likelihood of successful adoption.

- Phase 1: Proof of Concept and Pilot Projects. This initial phase focuses on validating the core technologies and processes within a contained, controlled environment. Selecting a specific area of the factory for a pilot project allows for targeted testing and analysis of results, helping to fine-tune the implementation strategy.

- Phase 2: Targeted Expansion and Integration. Once the pilot project proves successful, the next step is to expand the IoT infrastructure to other areas of the factory, ensuring seamless integration with existing processes and systems. This includes deploying more sensors, expanding data collection points, and testing scalability.

- Phase 3: Optimization and Refinement. This phase focuses on continuous improvement and refinement of the IoT system based on collected data and real-world observations. Data analysis, feedback loops, and iterative adjustments are critical for maximizing the value of the IoT investment.

Integration Methodologies

Choosing the right methodology for integrating existing machinery and processes into the IoT infrastructure is crucial. A well-defined methodology ensures compatibility and minimizes disruptions to existing operations.

- Modular Integration. This approach involves integrating IoT components in modular fashion. This allows for flexible expansion and modification without significant disruption to existing processes. Each module can be tested and validated independently before integration, reducing the risk of errors and ensuring compatibility.

- API-Driven Integration. Utilizing Application Programming Interfaces (APIs) allows for seamless communication between various systems and devices. APIs act as a bridge between legacy systems and the IoT platform, enabling data exchange and integration.

- Data Standardization. A standardized data format is crucial for efficient data exchange and analysis. This includes using industry-standard protocols and formats for data transmission and storage, ensuring compatibility across different systems and devices.

Legacy System Integration Challenges

Integrating legacy systems with modern IoT technologies can present significant challenges. Understanding these hurdles is vital for developing effective mitigation strategies.

- Data Compatibility. Legacy systems often use incompatible data formats or protocols, requiring significant conversion and translation efforts to integrate with the IoT platform. This necessitates careful planning and selection of appropriate tools and technologies for data translation.

- Security Concerns. Integrating legacy systems into the IoT environment introduces new security vulnerabilities. Addressing these concerns requires implementing robust security measures to protect sensitive data and prevent unauthorized access.

- Process Adaptation. Integrating legacy systems may necessitate adapting existing production processes to align with the requirements of the IoT system. This requires careful planning and coordination to minimize disruptions to existing operations.

Case Studies of IoT Success Stories

Real-world implementations of IoT in manufacturing showcase remarkable improvements in efficiency and profitability. These case studies demonstrate how businesses across various sectors are leveraging the power of interconnected devices to transform their operations. By understanding the strategies behind successful deployments, businesses can identify opportunities to optimize their own IoT initiatives.

Automotive Industry Successes

The automotive sector has embraced IoT to enhance production processes, improve vehicle safety, and optimize supply chains. One notable example involves a leading car manufacturer that deployed sensors throughout its assembly line. These sensors tracked real-time equipment performance, enabling predictive maintenance and reducing unplanned downtime. By anticipating equipment failures, the manufacturer minimized production delays and saved substantial costs.

Another success story centers around a vehicle manufacturer that used IoT to monitor vehicle performance data collected from the field. This allowed them to proactively identify potential issues and enhance vehicle reliability, leading to improved customer satisfaction.

Electronics Manufacturing Optimization

In the electronics industry, IoT has proven crucial for streamlining complex manufacturing processes and enhancing product quality. A major electronics company utilized connected sensors in their manufacturing facilities to monitor critical production parameters like temperature and humidity. This enabled them to maintain optimal conditions for manufacturing processes, resulting in higher yields and fewer defects. Another example involves an electronics manufacturer that integrated IoT devices into their supply chain.

This enabled real-time tracking of components, minimizing delays and ensuring timely deliveries.

Quantifiable Results and Challenges

Successful IoT implementations often yield significant quantifiable results. For instance, reduced downtime translates to increased production output, while improved yield leads to higher profitability. These improvements are often achieved by overcoming challenges such as data security concerns, integration complexities, and the need for skilled personnel. Effective communication and clear data visualization play a vital role in successful implementation.

Data security measures, including robust encryption and access controls, are crucial to protect sensitive information. Furthermore, addressing integration complexities through standardized protocols and well-defined data models is vital.

Success Factor Comparison

| Case Study | Industry | Key Challenges | Success Factors | Quantifiable Results |

|---|---|---|---|---|

| Automotive Manufacturer | Automotive | Data security, integration complexities, skilled personnel | Robust data security measures, standardized protocols, clear communication | Reduced downtime by 15%, increased production output by 10% |

| Electronics Manufacturer | Electronics | Data volume management, integration complexities, data interpretation | Standardized protocols, data visualization tools, skilled data analysts | Improved yield by 8%, reduced defects by 12% |

The table above provides a concise overview of the common success factors across multiple case studies. Successful implementation relies on robust strategies for data security, clear communication, and the development of skilled personnel to effectively manage the complex data generated by IoT devices.

Challenges and Considerations for IoT in Production

The integration of IoT into manufacturing processes presents exciting opportunities for efficiency and innovation. However, realizing these benefits requires careful consideration of potential hurdles. These challenges, if addressed proactively, can pave the way for successful deployments and sustained operational excellence. Ignoring them could lead to costly setbacks and missed opportunities.

Security Risks of Connected Industrial Devices

Connecting industrial devices to the internet introduces significant security vulnerabilities. Malicious actors could potentially disrupt production processes, compromise sensitive data, or even cause physical damage. Cyberattacks targeting industrial control systems (ICS) can have devastating consequences. Protecting these systems requires robust security protocols, including intrusion detection systems, firewalls, and regular security audits. Implementing multi-factor authentication and strong encryption is also critical.

Data Privacy and Security in IoT Environments

Maintaining data privacy and security is paramount in IoT manufacturing environments. Sensitive data about production processes, equipment performance, and employee information must be protected from unauthorized access and misuse. Regulations like GDPR and CCPA necessitate robust data protection measures. Data encryption, access controls, and secure data storage are vital components of a comprehensive strategy. Implementing strict data governance policies and regular audits is also crucial.

Skills Gap and Training Requirements

Implementing and managing IoT systems demands a skilled workforce. A significant skills gap exists between the current capabilities of personnel and the technical expertise needed to effectively deploy and maintain IoT solutions. Comprehensive training programs are essential to equip personnel with the necessary knowledge and abilities. Training should encompass aspects like data analysis, system integration, cybersecurity, and troubleshooting.

The shift from manual to smart factories in IoT production is huge, but understanding the underlying IT, OT, and IoT interplay is crucial. Knowing the distinct roles of these systems, as detailed in IT vs OT vs IoT: Understanding the Key Differences and Connections , is key to maximizing efficiency and minimizing potential pitfalls. This deeper understanding of the tech landscape empowers companies to build truly intelligent, interconnected production lines.

Developing internal expertise and fostering a culture of continuous learning is critical.

Maintaining Data Integrity and Reliability in Real-Time Production

Real-time data integrity and reliability are essential for optimal production processes. Data errors or inconsistencies can lead to inefficiencies, production delays, and quality issues. Robust data validation, error handling, and backup mechanisms are critical to maintaining the integrity and reliability of real-time data streams. Redundant systems and data synchronization protocols are vital to prevent disruptions and ensure data availability.

Implementing rigorous quality checks and data validation rules can further enhance data reliability.

Future Trends and Predictions: IoT In Production: From Manual To Marvel – The Rise Of Smart Factories

The future of manufacturing is undeniably intertwined with the ever-evolving landscape of IoT. Predicting precise trajectories is challenging, but analyzing current trends and emerging technologies allows us to anticipate the next wave of innovation. This section delves into the expected advancements in IoT technologies, focusing on how emerging technologies like augmented reality, virtual reality, and artificial intelligence are shaping the smart factory of tomorrow.The increasing integration of these technologies will not only optimize existing processes but also redefine the very nature of production, enabling greater efficiency, agility, and responsiveness to market demands.

The potential for significant gains in productivity and cost reduction is substantial.

Future Advancements in IoT Technologies

The evolution of IoT in production is a dynamic process, characterized by continuous innovation and development. Expect to see advancements in connectivity, data processing, and sensor technology. Faster, more reliable communication protocols will allow for real-time data exchange across the factory floor, leading to more responsive and efficient production processes. More sophisticated sensors will enable detailed and accurate monitoring of equipment and processes, offering granular insights into performance metrics.

Impact of Augmented and Virtual Reality

Augmented reality (AR) and virtual reality (VR) are poised to revolutionize the manufacturing experience. AR overlays digital information onto the real-world environment, providing workers with real-time instructions, maintenance guides, and process visualizations directly on their equipment. This will significantly reduce training time, improve worker safety, and increase operational efficiency. VR simulations can be used to train employees on complex procedures in a safe and controlled environment, allowing for more accurate and repeatable processes.

These technologies can also support remote maintenance, allowing technicians to virtually access and troubleshoot equipment from anywhere in the world, enhancing accessibility and reducing downtime.

Role of Artificial Intelligence in Optimization

AI is becoming increasingly critical in optimizing production processes and decision-making. AI-powered systems can analyze vast amounts of data from IoT devices to identify patterns, predict equipment failures, and optimize production schedules. Predictive maintenance is one significant application, where AI models can anticipate potential equipment failures, allowing for proactive maintenance and minimizing downtime. AI can also support dynamic production scheduling, adapting to fluctuating demand and resource availability, ensuring efficient use of resources and maximizing output.

Intelligent quality control systems powered by AI can detect defects and inconsistencies in real-time, leading to reduced waste and higher quality products.

Anticipated Impact on the Future of Manufacturing

The integration of IoT, AR/VR, and AI will fundamentally transform manufacturing. Factories will become more autonomous, responsive, and adaptable to changing market demands. This will result in increased productivity, reduced costs, improved quality, and enhanced worker safety. The potential for automation and increased efficiency will lead to a more streamlined and agile manufacturing process, empowering businesses to respond quickly to market fluctuations and maintain a competitive edge.

Furthermore, these technologies will create new opportunities for innovation and development, driving the creation of entirely new products and services.

Last Recap

In conclusion, IoT in Production: From Manual to Marvel – The Rise of Smart Factories isn’t just a technological advancement; it’s a paradigm shift in manufacturing. The benefits, from improved efficiency and quality to enhanced safety and worker well-being, are profound. While challenges like security and integration exist, the potential rewards are substantial. As we’ve seen, successful implementations across various industries demonstrate the tangible improvements possible.

This transformation is ongoing, and the future of manufacturing is undoubtedly smart. The journey towards smarter factories is well underway, and the future is bright.